Every component of PIXEL Raised Access Flooring is regularly checked during production process with our own measurement equipment laboratory following a rigorous control method to the highest standards.

Production - Inspection Standards

Every component of PIXEL Raised Access Flooring is regularly checked during production process with our own measurement equipment laboratory following a rigorous control method to the highest standards.

Static Load Resistance

Dynamic Load Resistance

Drop Impact

Measurement

Fire Classification

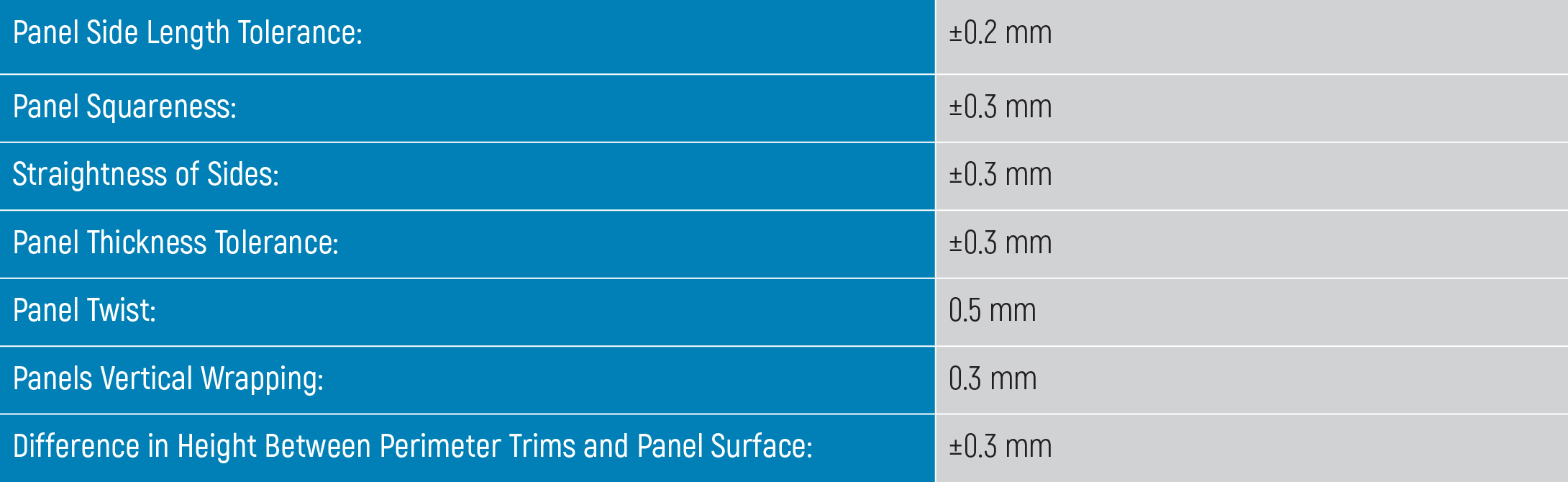

DIMENSIONAL TOLERANCE

Note: Limit panel thickness tolerance of the same batch floor is 0.3 mm.

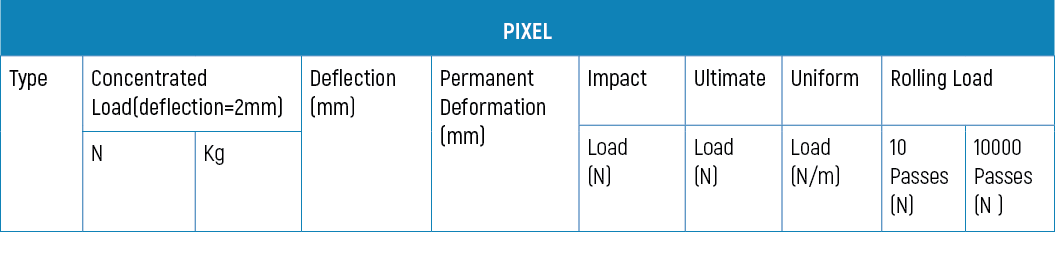

MECHANICAL PROPERTIES

• Load Performance of the Floor.

The load bearing capability of a raised access flooring system is determined by the type of access flooring panel specified.

• Impact Resistance

After the floor impact performance test, the permanent deformation of the floor surface should be ≤ 1.5 mm, and there should be no damage.

PEDESTAL AXIAL LOAD:

Axial load of adjustable pedestals should be > 20 kN.

FIREPROOF PERFORMANCE

The fireproof performance of PIXEL Raised Access flooring reaches B1 and A levels.

FLOOR APPEARANCE

Raised access flooring should be assembled finely, keeping the seams neat and tidy, firmly bonded, with no opened glue.Surface covering and finishes should be stain-resistant, non-slippery slip, with no visible chromatic aberration, blistering and defect, and without glaring.

The metal surface features a strong anti-rust layer.

The floor with galvanizing should have a metallic luster and no defects. The floor treated with spraying should be soft light, without obvious color difference, foaming and defects.